Tube filling machine is a machine that fills liquid, cream and other materials into a tube with a cap or nozzle at one end and seals the opening. It is widely used in various scenes that require tube filling and sealing, such as cosmetic tubes, pharmaceutical ointments, and daily chemicals.

Tube filling machine classification

Before talking about the working principle of the machine, we first classify the tube filling machine. According to the degree of automation, it can be divided into fully automatic and semi-automatic. According to the sealing method, it can be divided into ultrasonic sealing and heat sealing.

Fully automatic and semi-automatic

As the name suggests, the difference between the two is the degree of automation. In the tube filling machine, fully automatic usually means that as long as you prepare all the materials needed for the machine production, the machine can perform the next work fully automatically, without requiring you to keep guarding the machine, or manually What the machine does. The main problem faced by the fully automatic tube filling machine is how to ensure the stability of the machine, avoid unattended, machine failure shutdown and production stop. In order to solve this problem, our company has optimized the machine in many aspects, including adding induction electric eye detection, using a drive motor with high stability, and designing drop tube parts for multiple iterations. The automatic tube filling machine is suitable for mass production and is of great help in saving labor costs.

Semi-automatic tube filling machine refers to a machine that requires a worker to perform some manual operations during the operation of the machine. Semi-automatic machines are generally cheaper than fully automatic machines, and are suitable for small batch production.

Ultrasonic sealing and heat sealing

At present, there are two mainstream tube sealing methods in the market, ultrasonic sealing and heat sealing. Heat sealing is a more traditional way, by preheating the mold to heat and weld the end of the tube. Heat sealing has the advantage of simple structure, but because of its sealing principle, the high-temperature mold is always exposed to the air, and part of the energy is lost in the form of heat dissipation, resulting in high energy consumption of the machine, and the machine needs to be preheated.

from Wikipedia

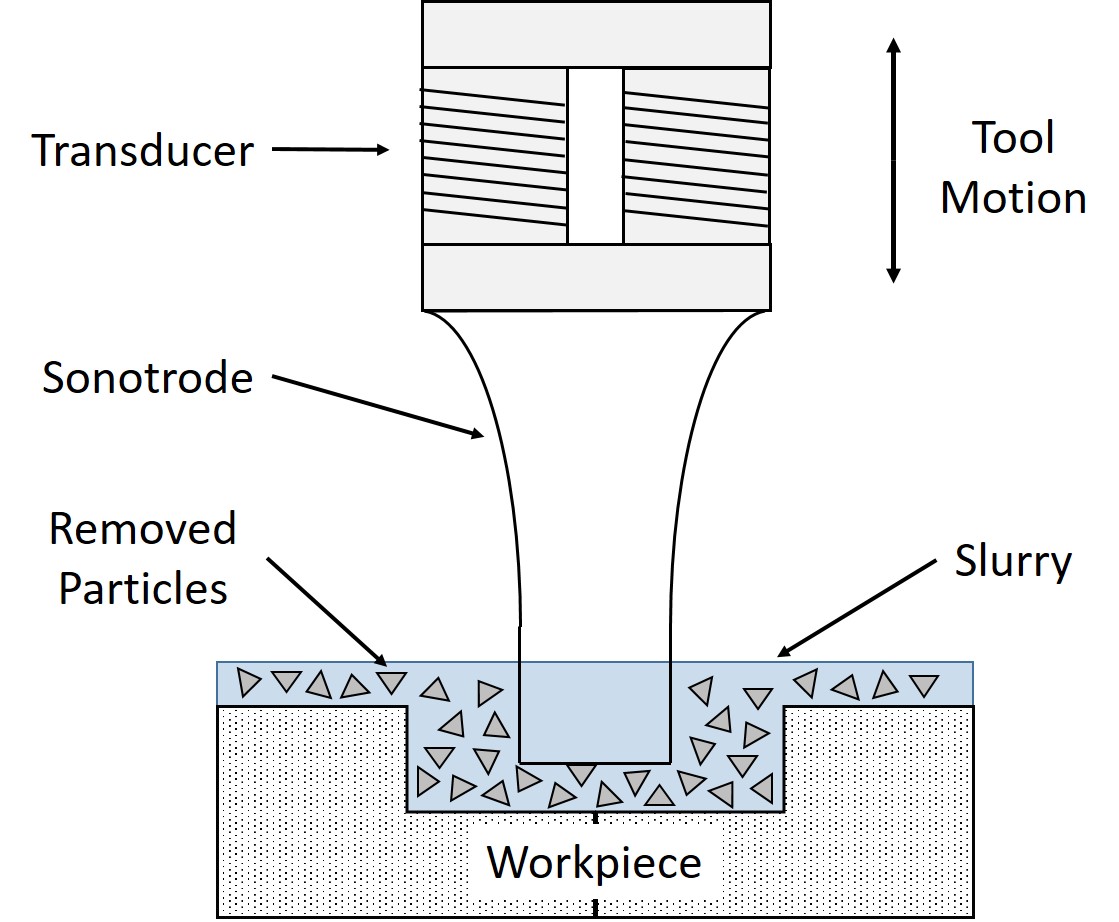

Ultrasonic sealing is a new generation of high-tech sealing method that is becoming more and more popular among the public. The sealing principle is to use ultrasonic waves to cause high-speed and small friction between the tubes, and to cause local molecular welding in a short time. The technology of using ultrasonic welding actually appeared as early as 1960, but because of the immaturity of the technology, it is known that the ultrasonic sealing technology has only been widely used in tube filling machines in recent years. Since the ultrasonic sealing only consumes energy at the moment of sealing, the ultrasonic sealing has the characteristics of low energy consumption, and it can be used without preheating. Another advantage brought by the precision of ultrasonic sealing is that the damage to the tube is relatively small, and the original coating integrity of the tube can be maintained.

Working principle of tube filling machine

After talking about the classification of tube filling machines, let's talk about the working principle of tube filling machines. Its working principle can be summarized as follows:

- Automatically take and release the tube;

- Use the color-coded electric eye to rotate the tube to the correct direction;

- Filling;

- Ultrasonic sealing and coding at the same time;

- Trimming off the uneven part of the tail;

- Automatic popup.

We are a professional manufacturer of tube filling machines. We have more than ten years of production experience and have provided high-quality services to different countries around the world. If you have needs for tube filling machines, welcome to contact us, you can submit your information in the contact form below, or contact us through the email in the upper right corner of the webpage.