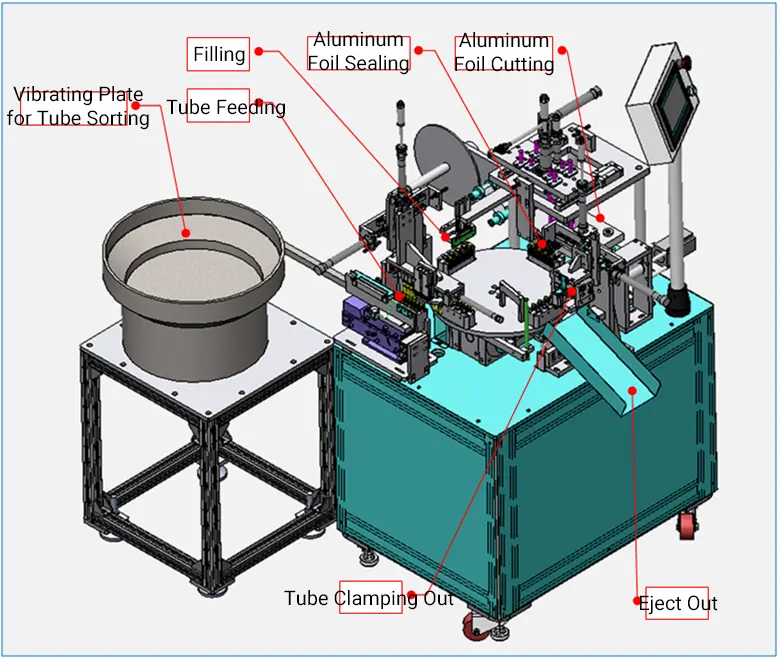

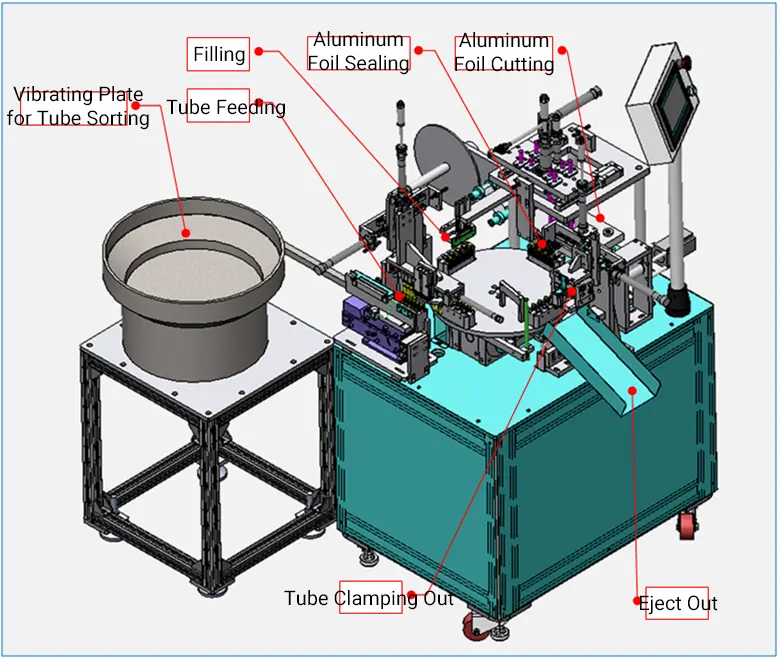

Fully Automatic Production Process:

- Sorting bottle: Vibrating the plate to sort bottle.

- Putting bottle: pneumatic manipulator automatically clamps 4 bottles and puts them into the mold.

- Delivery bottle: The turntable delivery the mold to the next process.

- Filling: 4 filling pumps fill.

- Sealing: Automatic feeding aluminum foil, mold cutting aluminum foil, automatic taking and placing aluminum foil, automatic hot sealing.

- Out of the bottle: The pneumatic manipulator takes the bottle and sends it to the unloading board for bottle discharge.

Perfect Automatic Detection Function

- Alarm for lack of bottle on vibrating plate

- No filling without bottle

- No aluminum foil without bottle

- Alarm for lack of aluminum foil

- Alarm for aluminum foil leakage

- Alarm for bottle leakage

- Sealing temperature is not reached, cannot be started and alarm

- Alarm for cylinder not in place

The Required Accessories

- Bottle size and shape (single ear and double ear) are different:

It may be necessary to replace the vibration plate, guide rail, mold, bottle needle and bottle glue.

- The size and shape of aluminum foil are different:

The blanking mold, aluminum foil suction nozzle and copper hot head may need to be replaced.

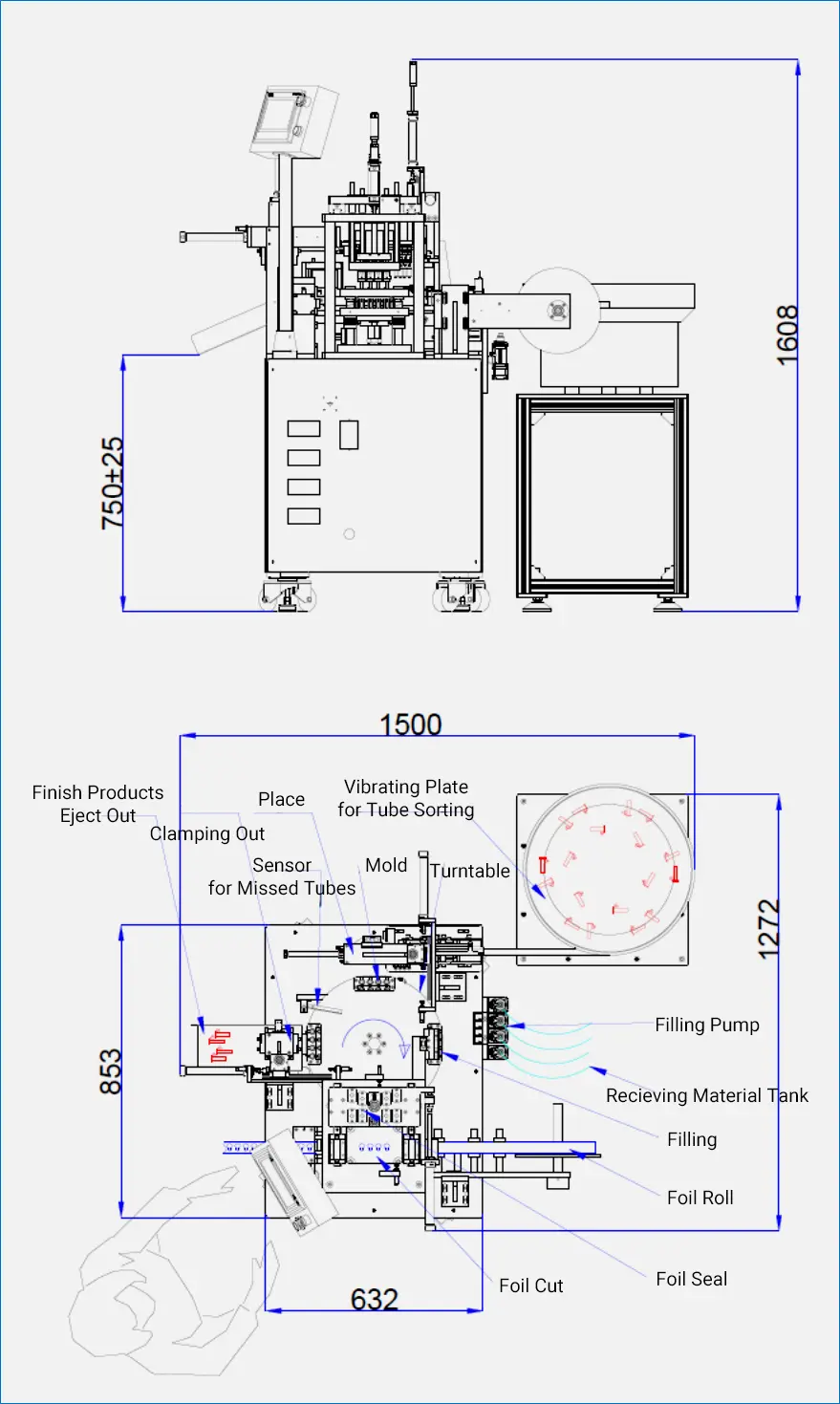

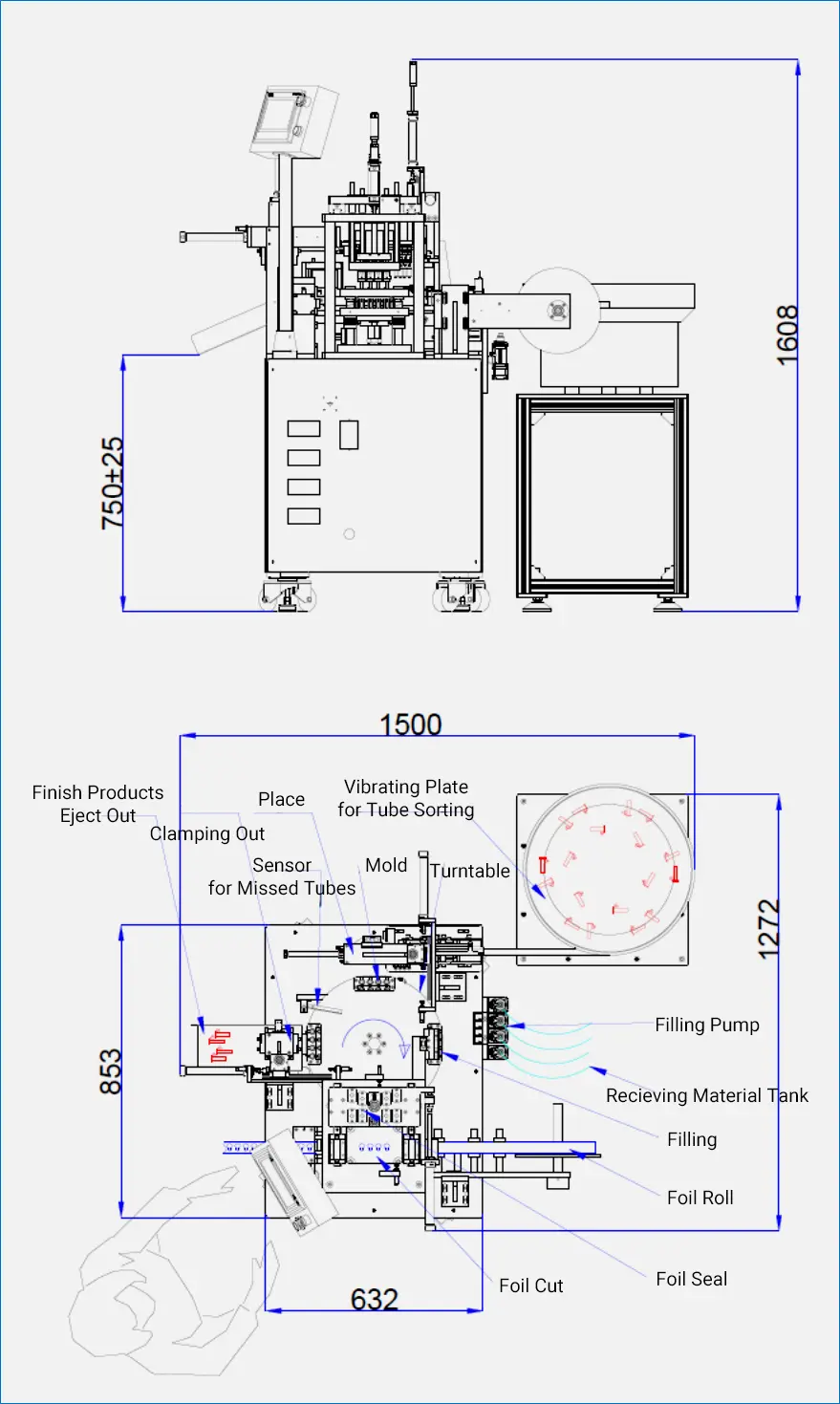

Technical Parameters

| Capacity |

3600pcs/h |

| Filling Method |

Plunger pump filling |

| Filling Range |

100-1000μL (Adjustable) |

| Filling Accuracy |

±2% |

| Power Supply |

220v, 1.5kw |

| Air Pressure |

0.6MPa-0.8MPa |

| Air Consumption |

200L/min |

| Dimension |

1500mm*1272mm*1608mm |

| N.W |

200kg |

Main Parts Origin

Made of 304 stainless steel and aluminum alloy. The contact part is 304 stainless steel and medical plastic tube. Designed according to the requirements of the new GMP, convenient for cleaning.

| Slide Rail Module |

HIWIN, TW |

| Stepping Motor |

XINJE, CN |

| PLC Touch Screen |

XINJE, CN |

| Pneumatic Component |

AIR TAC, TW/XINGCHEN, CN |

| Electric Eye |

DEUZE, DE |

| Filling Pump |

Step Driven Precision Ceramic Plunger Pump |

| Relay, air switch |

Schneider, FR |