Fully Automatic Vials Filling and Capping Machine Double Station

Overview

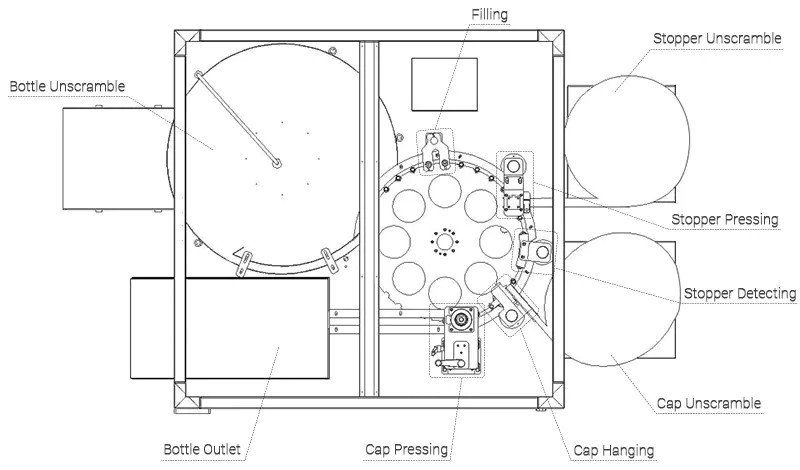

Rotary Automatic Vials Filling and Capping Machine is the equipment that can be used for automatic filling, cap screwing or cap pressing for vials, essential oil bottles and perfume bottles. The working process is divided into Bottle Sorting -> Filling -> Stopper Pressing(Set Up LYO rubbers) -> Cap Placing -> Cap Pressing -> Cap Pressing. The machine is characterized by stable production and strong versatility for packaging materials.Scope of Application

- Pharmaceutical medicine liquid vials, small glass bottles filling and capping.

- Cosmetic perfume, essential oil liquid filling and capping.

- Suitable for large scale production in high speed and low power consumption.

Feature

Vials Packaging

Vials Packaging- Vials, small glass bottles filling precisely. Suitable for 1R to 20R vials.

- Capping. Include bottle inside stopper(LYO rubbers) pressing and cap screwing or pressing.

- Auto arrange the bottle stoppers and caps to correct direction.

- Auto vials bottles feeding with large holder.

- The machine is universal for a variety of materials of cap because of high-quality steel sheet that has been quenched and hardened.

- The drive of turntable is servo drive which is smaller and lighter than other drives on the market. It can change the orientation freely and has fast speed.

- Warning when detecting vials without stopper.

- Easily change the height of working station for vials that has different height and the same radius.

- The input and output are on the same side, which is convinient for operator.

- The whole machine is compact and movable easily.

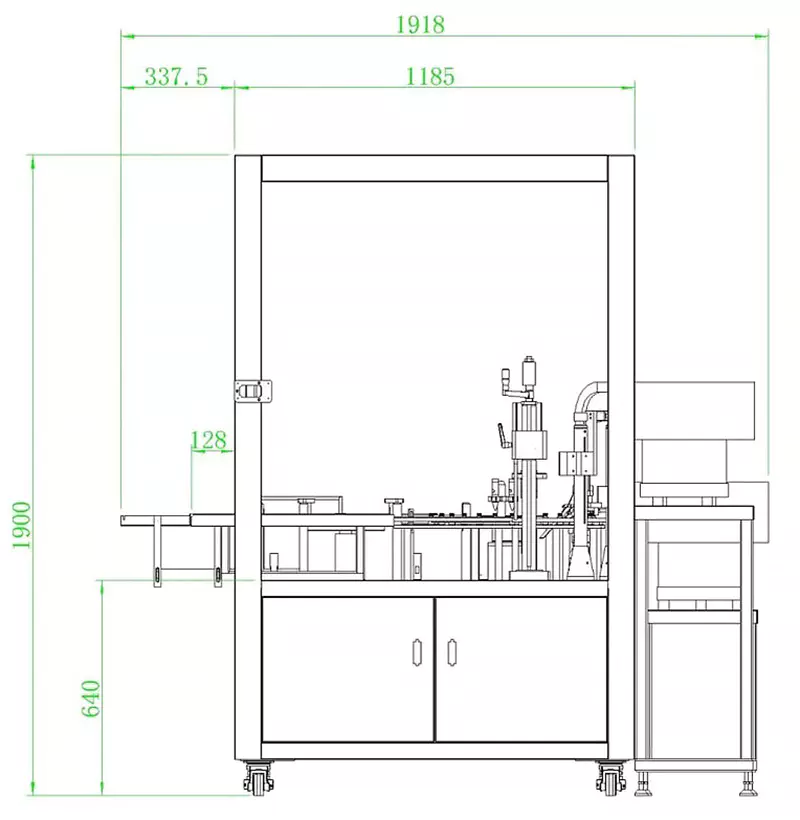

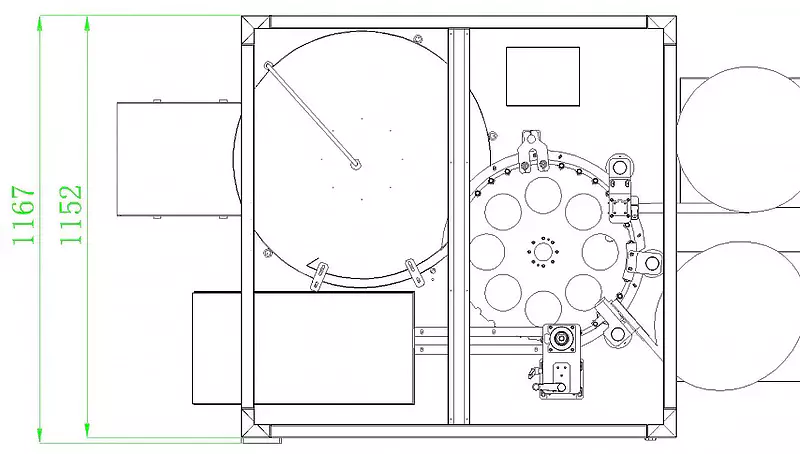

Dimension

Technical Parameters

| Bottle Unscramble – Auto Filling – Auto Stopper Pressing – Stopper Checking – Caps Hanging – Caps Pressing – Outlet | |||

| General Parameter | Model | HX-GX011 | |

| Voltage | 220V 50HZ (Customizable for 110V 60Hz) | ||

| Power | 2 kw | ||

| Production Speed | 40-50 Bottles/min (According to the dimension of bottles) | ||

| PS: Automatic stop when there is no stopper. The speed of concave or half plugging will be reduced. | |||

| Stopper Installation Type | Pressing | ||

| Cap Installation Type | Hanging | ||

| Cap Pressing Type | 4 Claws Crimping | ||

| Outlet Type | The push from turntable | ||

| Filling System | Filling Pump & Nozzle | 316L Magnetic Pump + Anti-Dripping Nozzle | |

| Filling Drive | Precision Servo Drive | Shenzhen | |

| Filling Error | 0.03-0.1 g | ||

| Filling Volume | 1-10ml | ||

| PS: The filling nozzles are anti-dripping, which keep your working station clean. | |||

| Viscosity of Material | lower than or equal to viscosity of oil | ||

| Power | 800W | ||

| Unscramble System | Conjoined or Split | Conjoined | |

| Motor Power | 120W (Speed Adjustable) | ||

| Speed of Unscramble | 100 bottles/min | ||

| Radius of Tray | 500 mm | ||

| Material of Tray | 304 Stainless Steel | ||

| Main Part | Turntable Power | 400W | |

| Servo Spliter | DELTA | CN, Taiwan | |

| Electromagnetic Valve | AirTAC | CN, Taiwan | |

| Relay | Honeywell | US | |

| PLC | (Pick one of two) SIEMENS / MITSUBISHI | DE / JP | |

| Touch Screen | SIEMENS | DE | |

| Photoelectric Sensor | KEYENCE | JP | |

| Inverter | (Only equip if ask) Danfoss | DK | |

| Power Supply | (Pick one of two) DELTA / MEANWELL | CN, Taiwan | |

| Air Switch | (Pick one of two) Honeywell / Schneider | US / FR | |

| Switch Button | Honeywell | US | |

| Other Parameter | Stopper Unscramble Device | 1 Set | Frequency Control |

| Cap Unscramble Device | 1 Set | ||

| Dimension | 1900 x 1918 x 1167 mm | ||

| Weight | 330 kg | ||

| Rack Material | 304 Brushed Surface Stainless Steel | ||

| Wheel | FOOT MASTER Wheel | ||

| Truntable Material | Anodised Brusher Aluminum Plate | ||

| Bracket | 304 Stainless Steel Stick | ||

| Waranty | Whole machine for 1 year | ||

Part Description

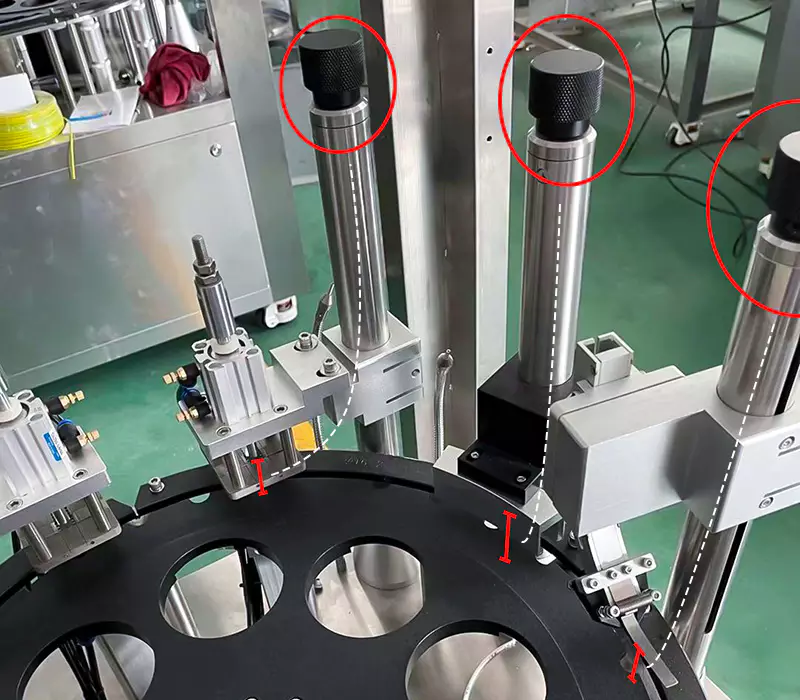

It can bear 38 kg and be adjusted to different height freely without tools.

Anti-Dripping Nozzle

It prevent dripping of filled material accidentely.

Filling Height Adjustment of Bottles

Can be Easily modified by the height of bottles. Just turn the knob directly without fixed handle.

4 Claws Crimping for Cap Pressing

Effectively compatible with the specifications of packaging materials commonly used in the cosmetic and pharmaceutical market.

Contact us

Email to us for catalogue and price list.